How to Make the Perfect Dart: Insights from Factory Production

Creating the perfect dart requires a seamless combination of precision engineering, advanced materials, and meticulous craftsmanship. In this article, we’ll explore the step-by-step process of producing high-quality darts from a factory perspective, highlighting key considerations in design, manufacturing, and quality control.

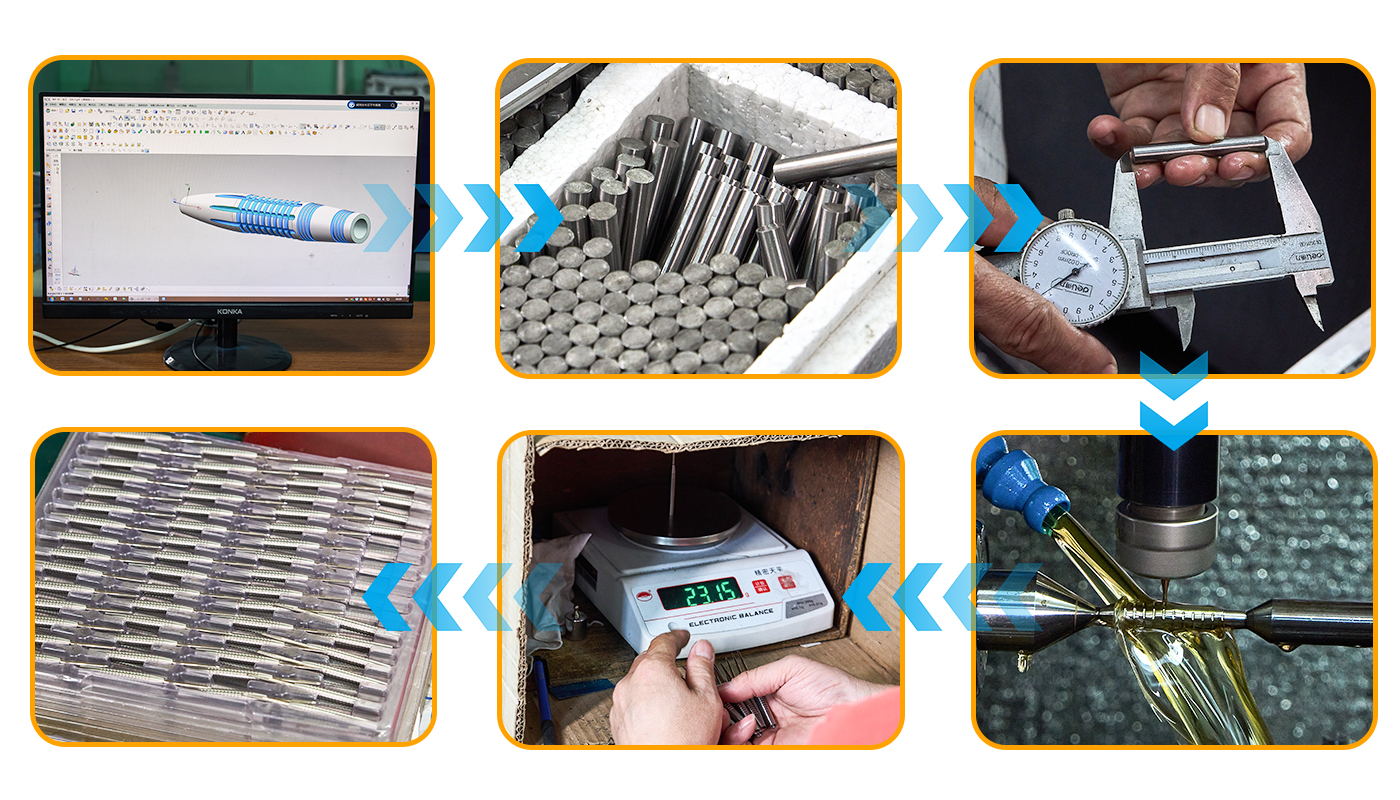

1. Design: The Blueprint of Precision

The process begins with designing the dart. Factors such as weight, shape, material, and balance are crucial for optimal performance.

- Material Selection: Tungsten is a popular choice for its density and durability, allowing for slim yet heavy darts.

- Aerodynamics: Designers use software simulations to analyze flight paths, ensuring stability during throws.

- Customization: Factories often offer OEM/ODM services, allowing clients to specify unique branding or features.

2. Material Preparation: Sourcing Quality Components

Factories source premium materials to ensure consistency and durability. Key components include:

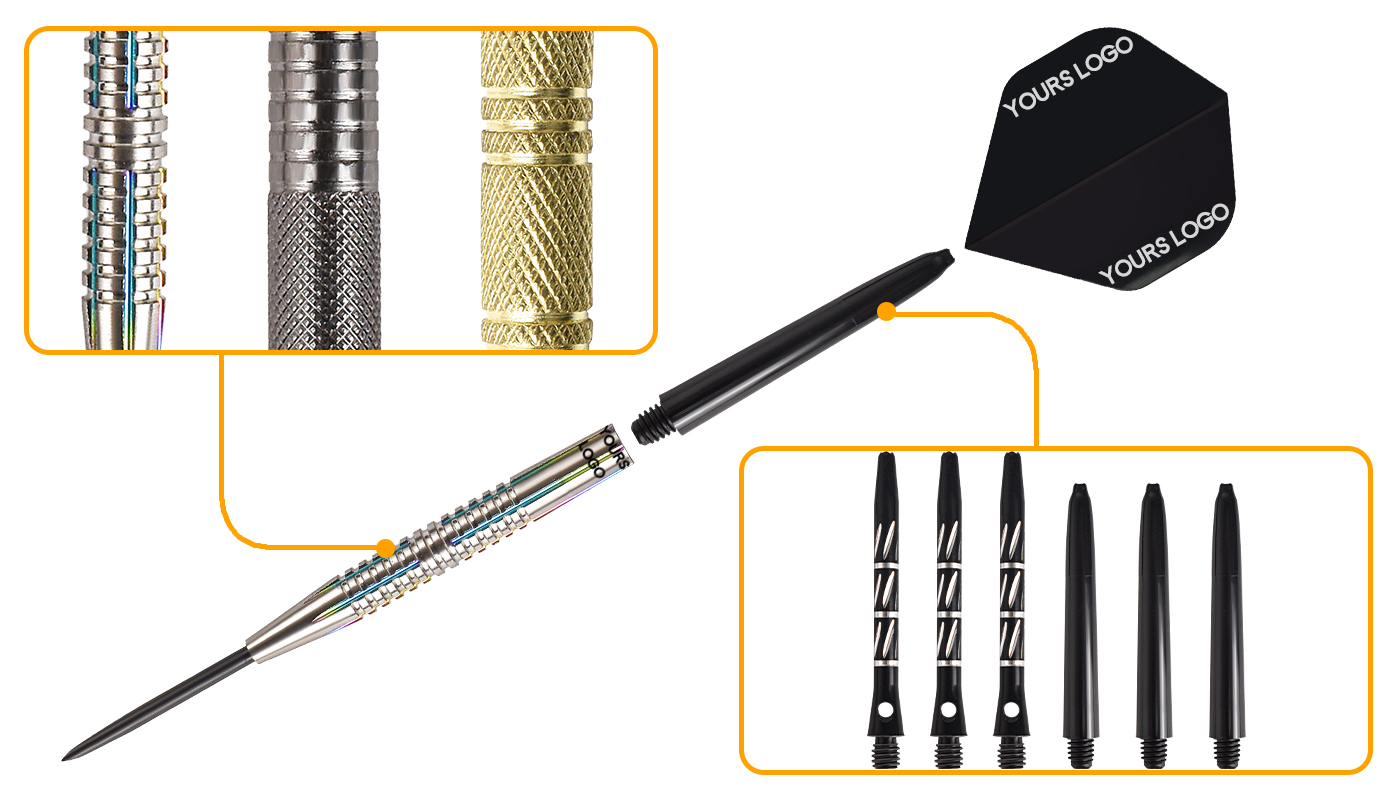

- Barrels: Precision-machined from tungsten or brass.

- Shafts: Commonly made of aluminum, carbon fiber, or plastic for different levels of flexibility and weight.

- Flights: High-quality polymer sheets are cut and printed to provide stability and branding options.

3. Manufacturing Process

Barrel Machining

The barrel is the heart of a dart. Factories use CNC (Computer Numerical Control) machines to ensure precise dimensions and intricate grip patterns.

- Weight Calibration: Every barrel is weighed and balanced to match specifications.

- Surface Finishing: Techniques like sandblasting, anodizing, or electroplating are used to enhance durability and appearance.

Assembly

Once individual components are ready, the dart is assembled:

- The shaft is screwed into the barrel.

- Flights are attached to the shaft.

- Tips (steel or soft) are added, depending on the dart type.

Printing and Branding

For custom orders, factories use UV printing or laser engraving to add logos, colors, and personalized designs.

4. Quality Control: Ensuring Perfection

Every dart undergoes rigorous quality checks, including:

- Weight Consistency: Ensuring all darts in a set are identical.

- Throw Tests: Testing aerodynamics and stability.

- Durability Tests: Assessing resistance to impact and wear.

5. Packaging: The Finishing Touch

Custom packaging is designed to protect the darts and appeal to target markets. Options include luxury gift boxes or eco-friendly solutions.

Conclusion

Producing the perfect dart is a meticulous process that balances craftsmanship, technology, and attention to detail. From material selection to precision machining and thorough quality control, every step ensures that players receive a product that enhances their game.

For factories, maintaining high standards in dart production not only guarantees customer satisfaction but also establishes a reputation for excellence in the global market.

Are Soft Tip Dart Boards Any Good for Competitive Play?

Latest List: What are the Top Custom Darts Manufacturers in 2025?

How to Sharpen Darts: A Guide from the Manufacturer's Perspective

Explore 6 Trusted Soft Tip Dart Manufacturers for Quality

Top List: What are the Top Brands of Darts in 2025?

Dart Shafts

Are aluminum dart shafts more durable than plastic shafts?

Yes, aluminum shafts have higher strength and durability, but are slightly heavier

FAQ

What if I encounter problems with my order?

We are committed to your satisfaction. If you encounter any problems with your order, please contact the customer service team. We will work with you to resolve any issues related to quality, delivery or product specifications.

Services provided

Do you provide private label services?

Yes, we provide customers with private label customization services, including brand logo design and packaging services for dart shafts, dart boards, and dart leaves.

Dartboard surrounds

Are the sizes of the guard universal?

Most guards are standard sizes and fit all dart boards with a diameter of 17.75 inches.

Dart bags

Does the dart bag support custom logos?

Yes, the brand can customize the exclusive logo according to needs.

Hot sale 23G 90% Tungsten Steel Tip Darts PVD Blue Engraving

High-density tungsten steel gives this dart excellent stability and accuracy, ensuring that every throw is more stable and accurate. Its compact design and non-slip grip make it suitable for all types of dart enthusiasts, especially for precise control and long-term training.

Wholesale 90% tungsten steel tip darts 21G PVD Color

This tungsten dart is made of high-density tungsten steel, which has excellent stability and accuracy. Its optimized weight distribution and streamlined design make each throw more stable, suitable for professional players and high-frequency training, providing an excellent gaming experience.

Factory custom wholesale 22g brass dart set

This steel-tip iron darts set features durable iron barrels, sharp steel tips, and high-quality flights for smooth, accurate throws. Ideal for home, bars, or competitive games, it offers reliable performance and excellent value for players of all levels.

Custom wholesale single-sided magnetic dart board

The magnetic dartboard is a safe and fun dart game tool featuring non-pointed magnetic darts, suitable for all ages. It is portable, easy to set up, durable, and eco-friendly, making it an ideal choice for family entertainment, parent-child interaction, and team activities.

Discover SKIPJACK’s Custom Dart Solutions

SKIPJACK offers darts custom-made solutions designed for excellence. Improve your game with our precision-crafted, customized darts.

Whatsapp: +8618502175060

SKIPJACK DARTS

SKIPJACK DARTS

SKIPJACK DARTS